The ultraviolet (UV) treatment process is an extremely quick physical process. UV light mutates and/or degrades DNA, the part of the cell that instructs an organism on how to function and reproduce.

When DNA is damaged, the organism cannot function, reproduce, or cause infection because its “instructions” are garbled or missing. It is rendered harmless and eventually dies.

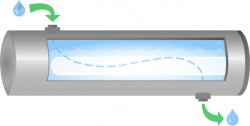

In the UV treatment process, water is purified as it runs through a stainless-steel chamber (also called a “reactor”) that contains a special UV-producing lamp. As the water flows past the lamp, the microbes in the water receive a lethal dose of UV. People can then confidently drink the water. Different organisms require different levels of UV energy (known as the UV dose) to disrupt their DNA.

How Do You Calculate UV Dose?

UV dose is expressed in mWs/cm2 or mJ/cm2. The accepted standard for most applications is 30 mJ/cm2. A slower flow rate results in a higher UV dose. The longer the chamber and the longer the water stays in contact with the UV lamp, the higher the dose. Most UV manufacturers have a variety of systems suitable for different dose requirements.

UV dose is determined by calculating two amounts: UV light intensity and time.

- Intensity is the quantity of UV light per unit area.

- Time is how long the water spends in the chamber (known as “contact time”).

Factors That Affect UV Dose

Different factors affect UV dose and UV’s ability to inactivate organisms in the water. If there is turbidity (large amounts of particles) or water hardness, microorganisms can “hide” behind these particles. This hampers UV transmittance (UVT), the amount of UV that penetrates the water. With a low UVT, “hidden” microorganisms don’t receive the required dose of UV light to deactivate their DNA, and the water isn’t properly treated.

Performing a water test will indicate what type of pretreatment a UV system requires to increase UVT and produce maximum effective treatment. The following chart shows the ideal state for maximum results:

| Parameter | Influence / Effect | Limits |

|---|---|---|

| UV Transmittance | Can affect system sizing requirements | > 75% UVT @ 254nm |

| Iron | Can affect both UVT and sleeve fouling | < 0.3 ppm (0.3 mg/L) |

| Hardness | Can cause sleeve fouling | < 120 ppm (7 gpg) |

| Turbidity | Can shield microorganism, post-UV contamination | < 1 NTU |

| Tannins | Can affect UVT and system performance | < 0.1 ppm (0.1 mg/L) |

Under NSF 55 Class A requirements, which may apply where you live, the required UV dose is 40 mJ/cm2. If you aren’t sure if local regulations require you to use an NSF-certified system, ask your local water treatment professional. They should be able to inform you about any laws or regulations concerning water treatment equipment where you live and help you find the right system to address your needs.

>> Next: Components of a UV System