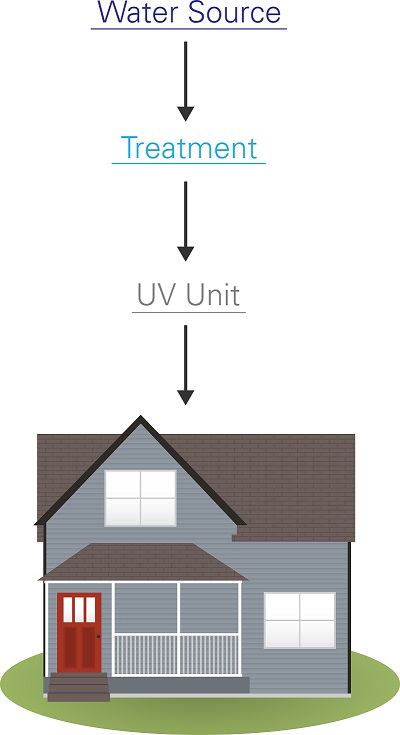

To ensure a UV system is as effective as it can be, pretreating the water is sometimes required.

UV Pretreatment ensures maximum effectiveness.

What is UV pretreatment and why is it important?

Ultraviolet treatment is an extremely effective way to combat microbial contamination in water. However, microbes have to be exposed to UV-C light in the proper amounts to be inactivated.

Water quality plays a major role in UV transmission (how much UV passes through the water). For the appropriate amount of UV-C light to inactive microbes, the UVT of the water must be ideal. Low UVT occurs when organic molecules or minerals are in the water that absorb or scatter the UV light, allowing microbes to pass through the UV system without exposure to the inactivation properties of UV-C.

Because of these pretreatment requirements, UV is not a standalone technology. Basic tap water generally comes out at 85 to 95% UVT. Something as common as the chemicals used to treat public tap water can absorb or scatter UV light. Most UV systems can function at UVT values from 95%. To reach this UVT level in well water, water testing and pretreatment are required to get the water to the proper quality for optimal operation.

The ideal water quality for UV treatment:

Turbidity < 1NTU (Turbidity units)

Suspended Solids < 10mg/L

Color – None

Total Iron < 0.3 mg/L

Manganese < 0.05 mg/L

Hardness <7 gpg (120 ppm)

Turbidity

The cloudiness or haziness in water that’s caused by particles that are generally invisible to the naked eye (such as organics, minerals, or chemicals), turbidity prevents UV light from reaching microbes because these substances can absorb or scatter UV light. Turbidity is undesirable in drinking water because it can contribute to taste and smell issues, and viruses and bacteria can attach themselves to these molecules.The best way to determine turbidity is to test the water and consult your water treatment professional for the most appropriate treatment option, depending on the molecules that are causing it.

Suspended solids

Small solid particles that remain suspended in the water, may or may not be visible to the naked eye. These particles are generally not soluble in water, scattering UV light and preventing effective treatment. Depending on the type of suspended solids, different treatments are needed to remove these contaminants.

Color

If the water is colored, it generally means there’s something in the water (turbidity, organic matter, suspended solids) that would prevent adequate UV transmission. Color is typically undesirable in drinking water and should be removed prior to water reaching the UV system to ensure effective treatment.

Iron and manganese

These two unpleasant minerals are often found in groundwater. They are not just undesirable in drinking water and for creating adequate UVT, but they can also stain appliances, fixtures, laundry, and clog plumbing. Both minerals collect on the quartz sleeve and foul it, preventing UV light from penetrating the water and allowing microbes to “hitch a ride.”

There are many ways to remove these elements from your water, but the best way to deal with your specific water quality conditions is to test your water and consult a water treatment professional to recommend treatment for your specific needs.

Hardness

Water hardness is an indicator of a high mineral content in water. This is common in groundwater, because surface water percolating through rock dissolves minerals as it passes through (sort of like water passing through coffee grounds) and carries them along with it. This hardness accumulates in the aquifer and stays in the water until it’s removed through a process called water softening.

Water hardness can reduce the amount of suds formed by soaps in water (making laundry soaps less effective), contribute to the formation of limescale on plumbing and appliances, and are a general nuisance. Although water hardness does not negatively impact human health, these other effects usually force homeowners to deal with the issue by softening the water. If you have water hardness (as indicated on a water test), talk to your water treatment professional for advice on the best way to remove it. Removing hardness is necessary for UV pretreatment, as hardness minerals will collect on the quartz sleeve and reduce UVT.

With essentially all types of UV treatment, preceding the UV system with a 5-micron filter is recommended. UV pretreatment will not only make your water taste and smell better, but it also ensures that your UV system works at maximum efficiency to protect you and your family 24/7.

If you have other water quality issues to address, contact your local water treatment professional for recommendations on a complete water treatment solution for your specific needs.

>> Next: UV System Maintenance